FUNDAMENTAL KNOWLEDGE OF ELECTRIC FAN

----o0o----

WHAT IS ELECTRIC FAN?

A main function of the electric fan is creating wind to cool the space through the principle of electric drive, each type of electric fan has 3 different wind functions to serve various customer’s needs. The principle of operation is air suction mechanism from the back when the fan blade moves and blows the air forward.

STRUCTURE OF ELECTRIC FAN:

Basically, the structure of an ordinary electric fan will include:

- External structure: Fan blade, Fan body, Fan guard and Fan base.

- Internal structure: Electric fan motor.

.jpg)

External structure:

- Fan blade: is a part that directly generates wind. Through the rotation of the motor, the movement of fan blade creates a pressure difference between the front and back, thereby creating wind. Today, there are some of the following patterns of fan blades: 3 or 5 or 7 blades. The factor that enables the effectiveness of the fan blade is strong wind thanks to the design of the fan blade.

- Fan body: the part that helps the fan stand in a right position when operating. Fan body is usually dynamically designed and can be installed or removed as needed.

- Fan guard: the simplest part of the fan, but it is important to protect users against danger, to avoid collisions between blades and users.

- Fan base: For some types of standing or table fans, there will be a fan base to help the fan stand firmly and fixed on a flat surface, keeping fan balance when the fan is in operation.

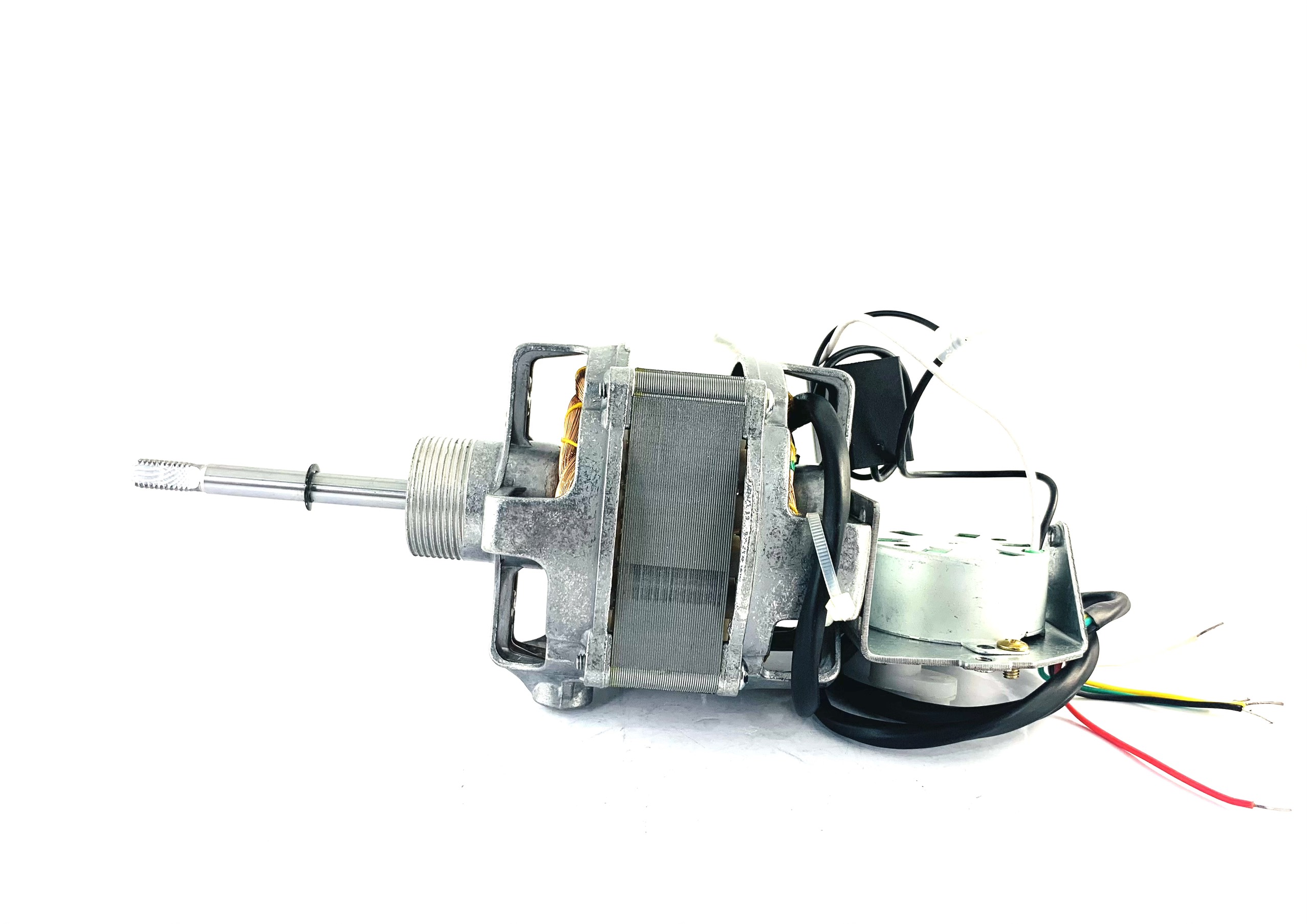

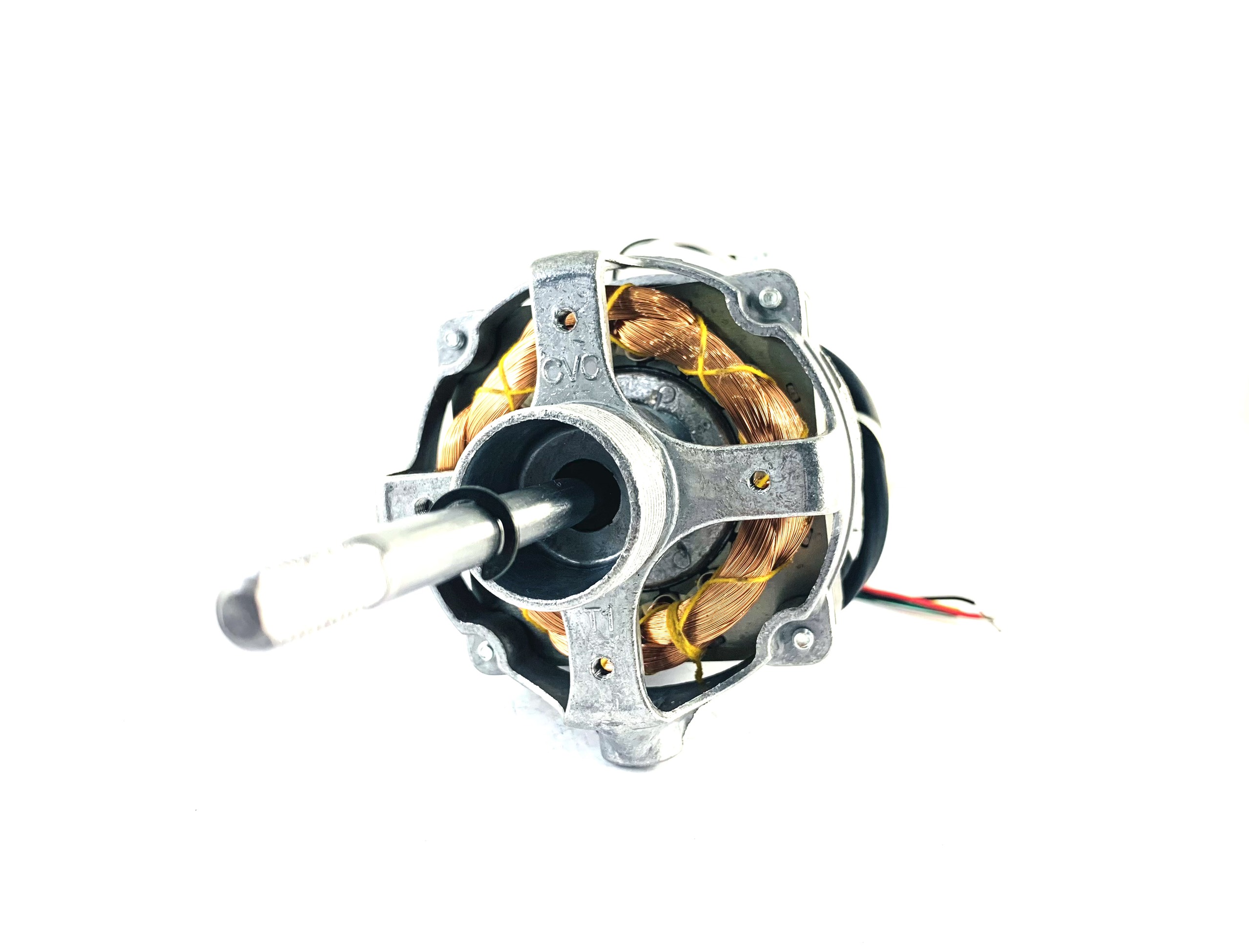

Internal structure:

- Electric fan motor: It is an electrically motivated part through the principle of electromagnetic fields, which is the heart that creates wind power for the electric fan. Today's electric fan motors are created with strict standards for motor performance, vibration, and noise in operation. Electric fans are considered good quality if they have low vibration, low noise and generate little heat during use.

STRUCTURE OF ELECTRIC FAN MOTOR:

- Stator: the stationary, non-moving part of the motor, composed of copper coils wound on the grooved core of the steel core, acting as a magnet (linked with the rotor to create a moving magnetic field motion). The winding of the stator consists of the runner set and the starter set.

- Rotor: a dynamic part, composed of a steel core linked to a steel reinforced shaft and a toothed tail to activate the synchronous movement of the gearbox when the motor is running.

- Capacitor: Used to create current to start the electric fan motor. Depending on the size of the motor, the manufacturer will use different types of capacitors with different parameters. The capacitor that Cuong Vinh uses is machined according to Cuong Vinh's standards.

- Aluminum housing (Front - Rear): Used to protect the stator as well as fix the concentric motor shaft when the rotor moves.

- Brass: Has the function to reduce friction force. Instead of using traditional lubricating oil, Cuong Vinh used PermaWick (Constructed from a blend and bond between fibers made with an oil formula) with much better efficiency. In addition, some electric fan motors are also used with better quality bearings. If motor uses normal lubricant, for 8,500 hours or more, more oil must be added, but for motors using PermaWick of Cuong Vinh, the usage time is up to 40,000 hours.

- Mechanical gearbox: Using the principle of mechanical drive to create the reciprocating movement of the motor. In addition, there are also some products that use electric navigation instead of the remote control function.

- Positioning washer (if using a semicircular core).

- Pin (if using round core)

The apperances of Cuong Vinh Electric Fan Motor

CLASSIFICATION OF ELECTRIC FANS IN THE MARKET:

- Standing fan: used on the ground, the height can be changed.

- Table fan: includes ordinary desktop fans and box fans. Regular desktop fans can rotate but the height is fixed.

- Orbit fan: understood to be fixed on the ceiling and capable of rotating 360° thanks to the diverter, it can cool to all locations in the used space.

- Wall fan: mounted on the wall, used in places with little space.

- Box fan: This type of fan is quite neat, rectangular, square or spherical, with a barrier that rotates in different directions, avoiding children's hands on the fan, keeping it safe if there are small children in the house.

- Industrial fan: Fan has a blade size of up to 750mm, industrial design and is often used in factories, workshops or places where a large amount of air is required.

- Ventilation fan: Also known as exhaust fan, the device is used in circulating air inside and outside the house, helping to expel hot air and bring cool air from outside to inside the house. Usually, exhaust fans are installed in places where air cannot circulate on its own.

With more than 29 years in the electric fan motor manufacturing industry, Cuong Vinh confidently offers the right solution to meet all the different needs of customers.

To better understand the product lines of electric fan motors provided by Cuong Vinh, please visit the link here: Electric Fan Motor