- Details

- Technical drawings

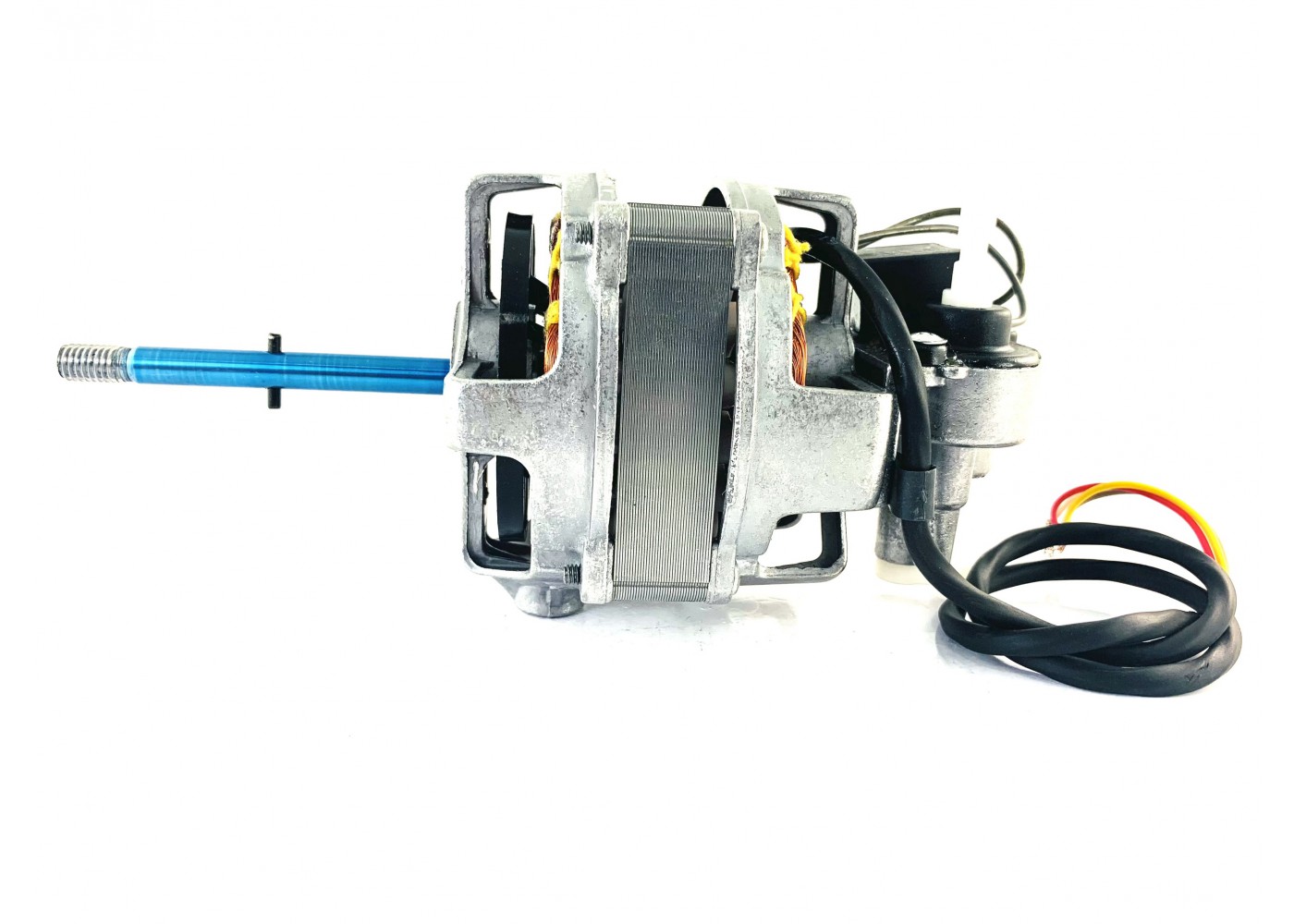

I. WHAT IS ELECTRIC FAN MOTOR ?

Electric fan motor is an electrically motivated part through the principle of electromagnetic fields, which is the heart that creates wind power for the electric fan. Today's electric fan motors are created with strict standards for motor performance, vibration, and noise in operation. Electric fans are considered to have good quality if they have low vibration, low noise and generate little heat during use.

II. STRUCTURE OF ELECTRIC FAN MOTOR:

- Stator: A stationary, non-moving part of the motor, constructed with copper wire wound on the grooved core of the steel core, acting as a magnet (linked to the rotor to create a moving magnetic field). The winding of the stator consists of the runner sets and the starter sets.

- Rotor: As a dynamic part, the structure consists of a steel core linked to a steel shafting and a thread tail to activate the synchronous movement of the gearbox when the motor is running.

- Capacitor: Used to create a current to start the electric fan motor. Depending on the size of the motor, the manufacturer will use different types of capacitors with different specifications. The capacitor that Cuong Vinh uses is produced according to Cuong Vinh's standard requirements.

- Aluminum cover (Front - Rear): Used to protect the stator as well as fit the motor shaft straight when the rotor is moving.

- Brass bearing: Has the function to reduce friction. Instead of using traditional lubricating oil, Cuong Vinh uses "PermaWick - Made In USA" (Constructed from a blend and bond between fibers made with an oil formula) instead with much better efficiency. Additionally, some electric fan motors are also used with better quality ball bearings. If the motors uses grease or lubricating oil, from 8,500 hours onwards, the oil must be added into the motor. However, for the motors using PermaWick, the time of usage is up to 40,000 hours.

- Gearbox: Using the principle of mechanical drive to create the reciprocating movement of the motor. In addition, there are also some products that use electric gearbox instead to use remote control function.

- E-lock washer (if using a half-moon shafting).

- Pin (if using round shafting)

III. PRINCIPLE OF OPERATION:

- When a current flows in the copper wire wound on the ferromagnetic core (also known as the silic side) made of thin pieces of silic tole that are put together to create a force acting on the rotor part. The position of the copper wire (including the running wire and the starting wire) are placed apart, so the effect is to shift the phase of the capacitor. From that, it will create in the stator some attraction forces that are not in the same direction.

- Since the two suction forces are different, a rotating magnetic field appears in the stator cavity, which will cause the rotor to rotate. To change the speed of an electric fan, the manufacturer usually wraps several turns of the wire in common with the running wire.

- Every time the current tends to increase or decrease due to the change in resistance of the coil, it will create a stronger or weaker magnetic force, causing the motor to run faster or slower.

- The speed (Rpm) of the electric fan motor includes:

o Speed 1: Low wind

o Speed 2: Medium wind

o Speed 3: Top wind

|

No. |

TYPE OF FAN BLADE |

DIMENSION |

STATOR |

|

1 |

12 Inch |

300 |

75x46x12 |

|

2 |

16 Inch |

400 |

75x46x16 |

|

3 |

18 Inch |

450 |

75x46x22 |

|

4 |

20 Inch |

500 |

110x65x20 |

(A reference table for some types of fan blades and stators used. Up to different size and weight of fan blades, appropriate stators are used)

IV. STRENGTHS OF CUONG VINH MOTORS COMPARED WITH OTHER PRODUCTS :

- Advanced and semi-automatic production lines according to Taiwan standards.

- Strict, almost closed production process: from winding electromagnetic wires to die-casting for aluminum cover of electric fan motors.

- Raw materials imported directly from the countries with high standards such as Japan, Taiwan, United States and China.

- More than 28 years of experience in the manufacturing of electric fan motors in Vietnam, being a partner with the best domestic fan brands like: Senko, Yanfan, Bifan, Lifan, Super Win, etc.

- Export to over 10 countries in the world including Philippines, Egypt, Thailand, Malaysia, Indonesia, Taiwan, India, some Middle East countries, etc.

- Experienced design engineer, all products designed to best suit each client’s demands.

- The factories equipped with the modern machinery and production lines, along with more than 800 skilled production workers with many years of experience.